The idea of pin factory visits goes back to Adam Smith, who at the end of the 18th century used the production of pins to illustrate the increase in productivity through the division of labor.

As one of the largest technology service providers and electronics specialists in Germany, the technology company TQ Group offers tailored and innovative solutions to a wide range of industries, from development, production and other services to product lifecycle management. It is active in the fields of E²MS (Electronic Engineering Manufacturing Services), embedded systems, drives, robotics, automation, medical applications as well as aviation and avionics.

In addition, TQ provides a complete range of its own products, such as embedded modules, base boards, human-machine interface systems, and drive and automation solutions. TQ also combines both as an ODM (Original Design Manufacturer). On the basis of its modular service and solution portfolio, the company develops and produces customer-specific products internationally, relying on “Made in Germany”. It is thus exemplary in the area of innovation in many respects and can provide science with interesting insights into the reality of innovative companies in Germany.

Insights at three sites

The team of the economics department visited three sites in six hours. The first route led to the company headquarters in Gut Delling near Seefeld in Upper Bavaria, where the doctoral students and postdocs, together with Dietmar Harhoff, had the opportunity to exchange ideas with the CEO and TQ founder Rüdiger Stahl and learn about interesting topics related to innovation, technology and development. Stahl spoke about the company's history, evolution – from a 2-man firm in 1994 to an international technology company – and innovation strategy. The framework conditions, challenges and regulatory restrictions for innovative companies in Germany came up again and again:

The global economic situation presents German companies with a variety of challenges. Fragile supply chains, geopolitical crises and protectionist laws such as the U.S. Inflation Reduction Act are impacting the ability of German companies to plan and compete. There is a particular need for action in the area of innovation. This also includes traditional sectors such as mechanical engineering and hardware manufacturing, in which continuous innovations must be pursued. Targeted measures are needed to sustainably strengthen innovation in Germany and make German companies competitive on an international level.

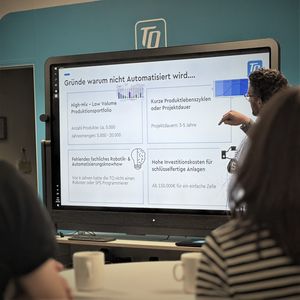

At the second site in Inning am Ammersee, Head of Production Julian Hornung gave the group insights into the fabrication of drive systems, from high-performance drives for e-bikes to RoboDrives. Finally, at the third location in Durach, the team took an in-depth look at automation and spoke with Sören Bruckmann, Head of TQ Robotics, Head of Sales Robert Vogel, and Georg Weiß, who heads R&D in Durach. The most debated question was why small and medium-sized companies in Germany lagged so far behind in automation.

In the showroom, a postdoc with research focus on automation and human-machine interactions had the opportunity to test the operation of a so-called cobot, i.e., a collaborative robot that works together with humans and is not separated from them in the production process by protective devices. The final leg of the journey took the team to the Durach production halls, where robots also produce robots.

The Institute’s researchers took away a lot of inspiration and some real-world and practical insights. More pin factory visits are to take place.

To the TQ company website.